Characteristics

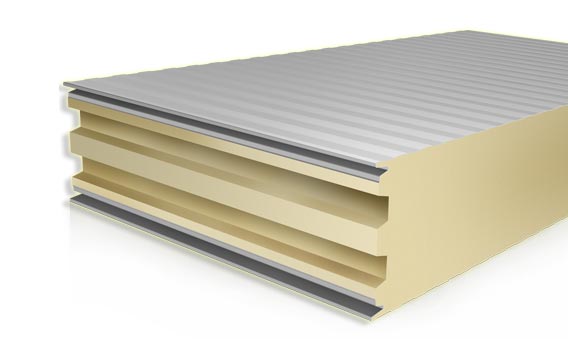

The chemical reaction involved in the production of polyurethane is exothermic, for this reason the produced panel releases a large quantity of heat that should be dissipated properly before stacking to avoid deformation of it.

An optimally designed cooling system is a significant requirement in achieving an optimal product quality and to avoid productions affected by deformations, bulged exteriors and wavy surfaces.

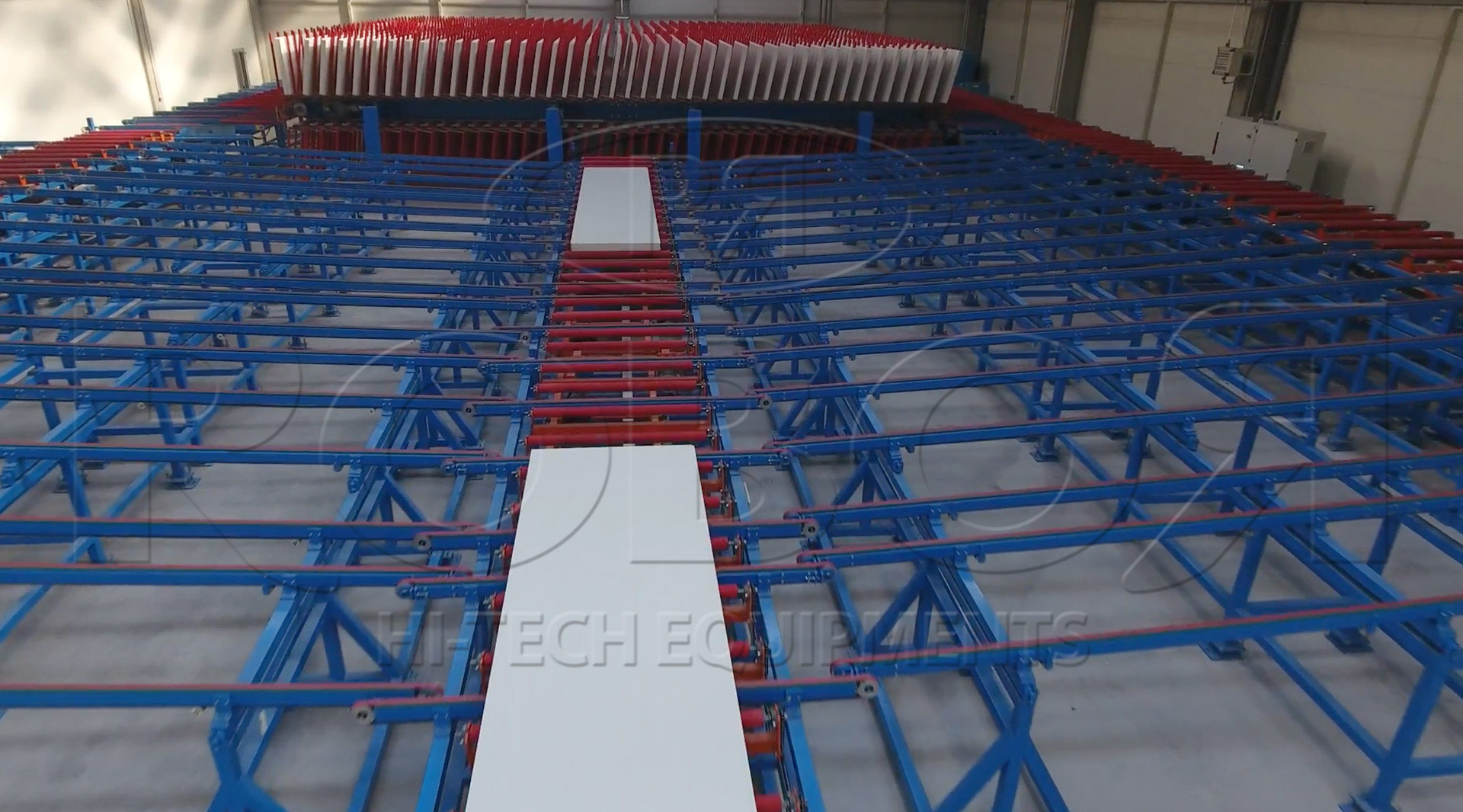

The cooling system is designed to load the panels in vertical position inside a conveyor system that allow an efficient heat dispersion.

To save valuable space we develop this machine according to the customers production requirements and assuring the maximum number of panels to be properly dissipated in the minimum space.