Characteristics

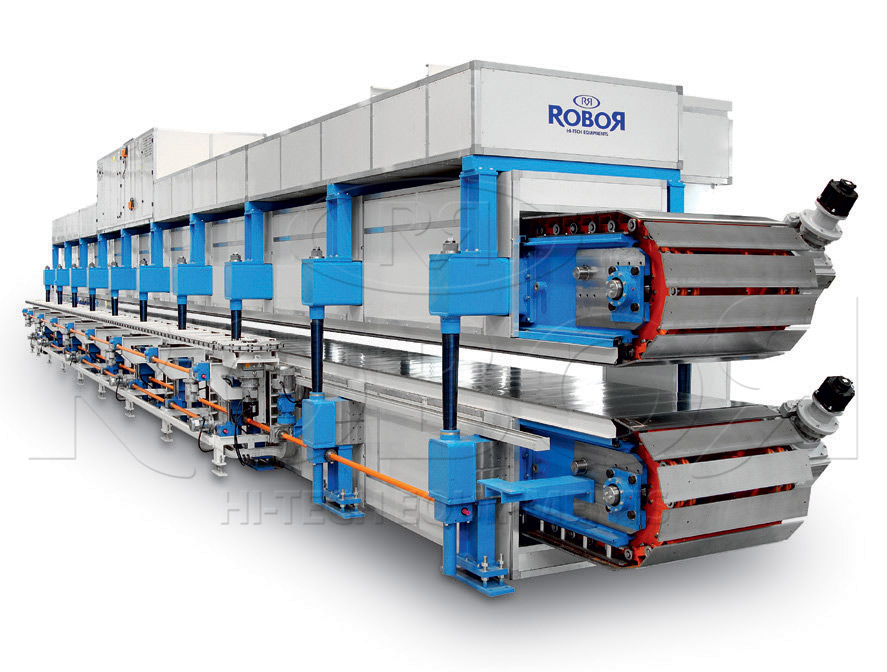

The continuous press is the key stage of the sandwich panel production process, trend-settling for the capacity and quality of the manufactured products.

This machine is made by two opposed conveyor belts that controls the pressure and heat generated by the panel with the aim to:

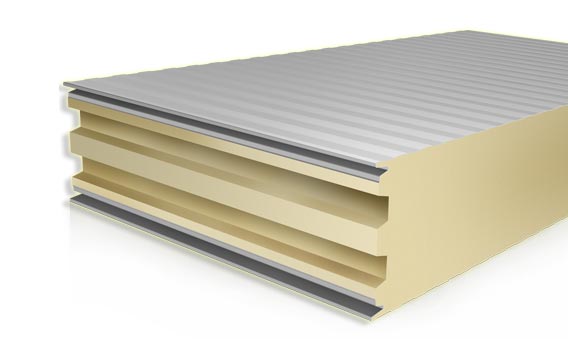

- Assist and control the foam structure expansion in order to ensure the optimal polymerization reaction;

- Make the perfect bonding between metal sheets and insulating materials;

The two belts are made by a series of superior grade steel slats characterized by its high strength and surface hardness. Due to special mechanical machining the finest surface finish is achieved and ensures excellent heat transfer, absolute flatness and planarity, low rolling resistance as well as long lifetime.

The two conveyors are independently heated and thermally insulated resulting in a homogeneous temperature distribution, highly efficient transfer of heat and low consumption values for electricity, thermal energy and lubricants.

The lifting movement of the upper conveyor is made by electric screw jacks and grants production of panels ranging from 15mm to 300mm.

The side containments installed on the double belt permits the production of panels width ranging from 400mm and up to 1200mm. This range is allowed by motorised movement by electric screw jacks on linear guides.