Characteristics

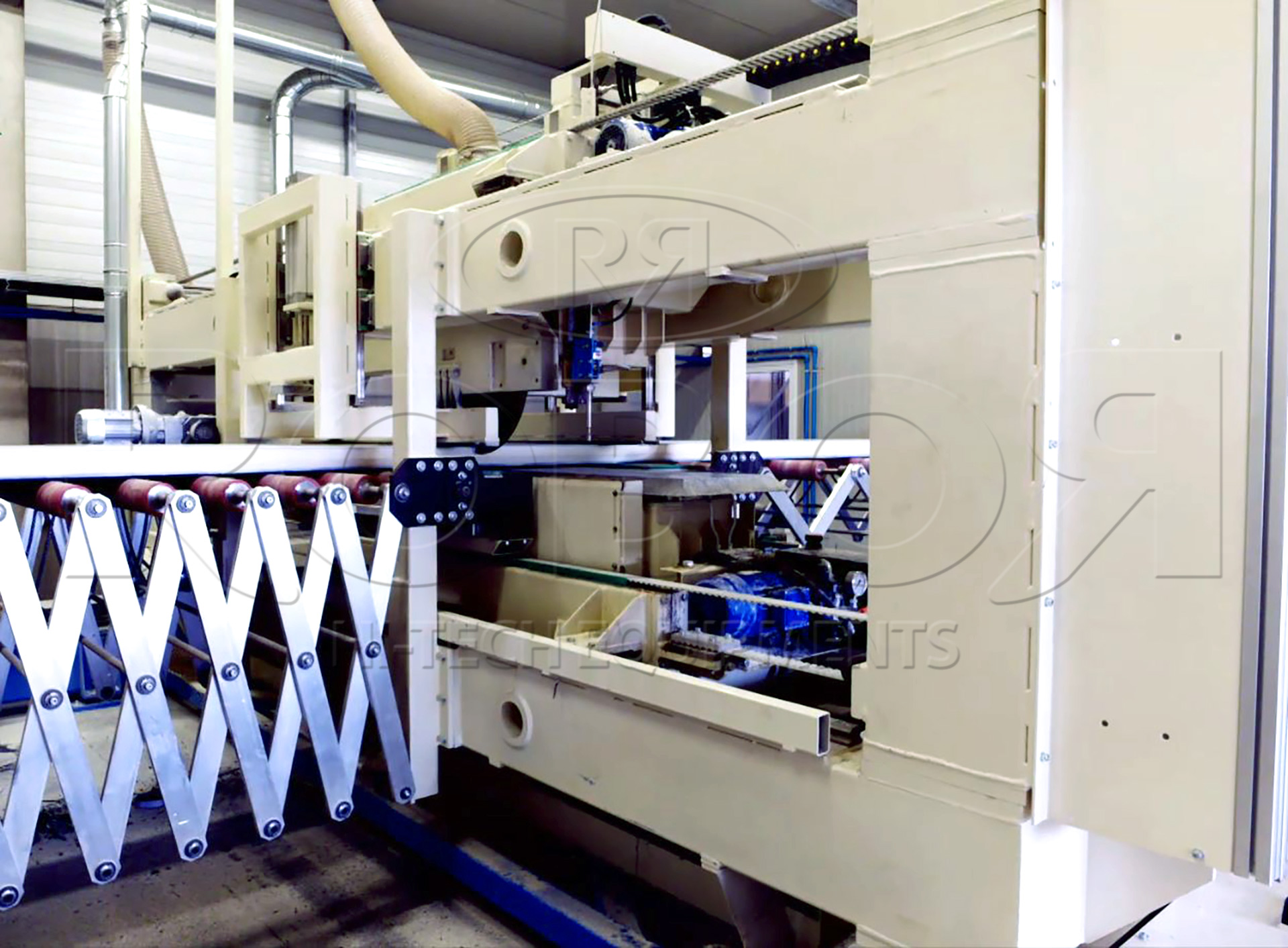

The panels made in the continuous production line are transversally cut to length by an electronically programmed and controlled flying cutting machine equipped with band saw and/or optional circular blade saw configuration, according to the specific production needs.

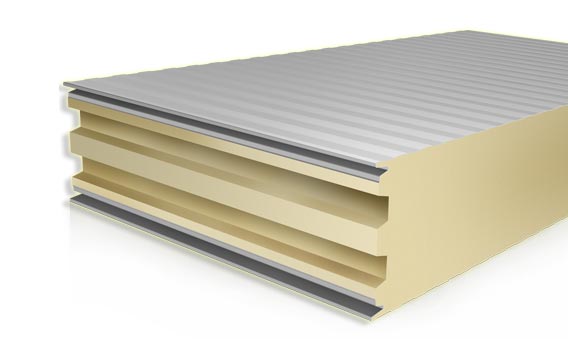

Our well known cutting technique mixed with the premium grade of the tools and equipments used come together to avoid sharp-edges and to produce clean, accurate and virtually burr-free cuts on steel, copper, aluminium and flexible facings.

The band saw is equipped with a 180° reverse turning system of the blade that allows a fast cutting sequence of the panel on the both crossing sides.

On the front of machine can be installed a cutting system with circular blade saw specifically designed to obtain hi-precision cuts on both foam and metal facings that will ensure a clean overlapping for the ribbed and roof-tile panels.

Moreover the cutting machine work is performed on a sound absorbing cabin with suction and filtering units in order to provide and maintain a safe and healthy environment protected from dust and noise.